On October 28, I delivered the following remarks as part of the Moses Greeley Parker lecture series in Lowell, Massachusetts:

“Nothing of Francis Cabot Lowell’s utopia has stood the test of time,” asserted architectural historian John Coolidge in 1942. The textile cities of central New England, including Lowell, Lawrence, and Manchester (N.H.) were “sports in the general line of American industrial evolution, transitory as ideal communities, unimportant as models,” he concluded.

Not so fast, I say. It’s not totally clear what Coolidge, who was writing in his book Mill and Mansion: A Study of Architecture and Society in Lowell, Massachusetts, 1820-1865, had in mind. But whether or not Lowell served as a model, many of its features reappeared over several decades—indeed over a couple of centuries–in industrial settlements from coast to coast.

Let’s quickly review the Lowell formula.

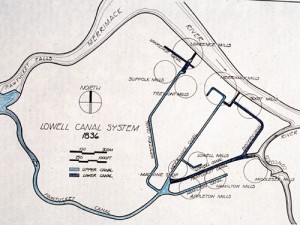

First, what would become a large-scale industrial town was built from scratch on mostly undeveloped land. In 1821, when would-be developers Nathan Appleton, Patrick Tracy Jackson, and Paul Moody visited the site of the future city, there were no more than a dozen houses and a couple of canals circumventing the falls of the Merrimack River, intended to make the river navigable. Quietly purchasing the land, and putting together an initial store of $600,000 in capital, they began the Merrimack Manufacturing Co. This initial venture would be joined by multiple other firms in the next several decades—firms sharing interlocking directorates and similar management structures, marketing their textiles via the same Boston commission houses, and paying identical wages. The town itself, buildings and streets, was to a considerable degree, designed by the manufacturing company’s “treasurer,” or on-site chief executive, Kirk Boott.

Secondly, the technology employed at Lowell borrowed existing methods but vastly improved upon it. Famously, both Samuel Slater of Rhode Island and Francis Cabot Lowell spent time at British factories and attempted to memorize just how such gizmos as Arkwright water frames worked. But the importance of such piracy can be exaggerated: Innovation and improvements were key to success; and equal in importance to the technology at work on the factory floor were the hydraulic innovations that led to an elaborate system of canals and water power.

Thirdly, there was the matter of the labor force. Throughout the 19th century, America suffered from a labor shortage, and this was particularly the case in the early years of the U.S. industrial revolution. Rhode Island addressed this issue by using children: Samuel Slater’s first mill on the Blackstone River at Pawtucket had a workforce of seven boys and two girls, ages seven to twelve. The Lowell capitalists famously looked elsewhere—to a pool of unmarried young women recruited from across the rural areas of New England. These young ladies were housed in boardinghouses under the strict supervision of older women “boardinghouse keepers”; they observed curfews, spent their leisure hours attending improving lectures, writing verse, and playing the boardinghouses’ pianos; and they were required to attend church.

Their behavior was closely watched, with companies able to fire any operatives charged with immoral conduct such as drinking alcohol or attending dance classes. In exchange, the workers’ pay–$12 to $14 per month in the 1830s—compared well with other alternatives. (After 1850, the workforce became more mixed, and increasingly immigrant workers of both sexes were employed.)

Let’s jump ahead in time a bit—to 1942. In that year, another would-be developer of a massive industrial complex arranged to take possession of 56,000 acres of farmland in East Tennessee. The methods involved were a tad more ruthless, for this time, management was the United States government, and its enterprise was the development of the atom bomb.

Employing the governmental prerogative of eminent domain, the government went into federal court and filed a “declarations of takings,” which had the effect of abruptly evicting the farmers who occupied the area. Some got as little as two weeks’ notice that they had to get out; some were told they’d better get a move on, because the government was building an artillery range and soon bombs would be falling on their former property.

As the farmers left, some crossed paths with the thousands of construction workers who were coming to build a new city: Oak Ridge, one of three supersecret locations central to the Manhattan project.

Technology: Oak Ridge and the Manhattan Project depended to a degree upon existing technology, developed in university laboratories. But really, the nuclear scientists there and at Los Alamos, N.M., and Hanford, Wash., were pioneers. Three vast factories appeared at Oak Ridge, each doing different things: At the complex of 268 buildings known as Y-12, electromagnetism was employed to split uranium atoms, isolating the U-235 isotope from U-238. The 42-acre gaseous-diffusion plant, K-25, attempted to part the isotopes employing a different method. The relatively small X-10 plant concentrated on the manufacture of plutonium.

Perhaps one of the most striking similarities to Lowell lay in the workforce, its housing and recreation. Among the great number of workers at Oak Ridge was a large pool of unskilled young women, many of whom were housed in dormitories.

Much of the work done by Lowell’s women was unskilled labor; at Oak Ridge, the work performed by the “hillbilly girls,” as they were condescendingly known, required even less skill: In fact, in the words of the Manhattan Project public-relations officer, they had “not the faintest idea of what their jobs were about.” Many sat in a control room, on stools spaced far enough apart to discourage communication, and for 6 days a week, 10 hours a day, silently adjusted dials that controlled the electromagnetic process. They were purposely misinformed about the actual product and punished if they asked questions or showed any initiative.

As at Lowell, the government organized all housing and construction—including thousands of single-family homes, 14 dorms, 3 apartment buildings, schools, and churches—along with recreation that included movie houses, bowling alleys, a library, and a riding academy. For the “hillbilly girls,” the environment was even more restrictive than that at early Lowell: Dorm rules barred cooking in the rooms, consuming liquor, gambling, and receiving visitors of the opposite sex. And they were watched, not merely by boardinghouse keepers but by military guards.

To be sure, there was much about Oak Ridge that was unlike any other town existing before or since. 75,000 people worked there during the height of World War II, having moved there without any idea of the work to be performed—all top-secret. It was a totally closed community, surrounded by wire fences and lookout towers and guarded by 5,000 police. Even so much as a letter to a relative that disclosed too much about goings-on would get you fired—and kicked out of the community.

All the same, my point is that company towns from the time of Lowell and right up to today have always had a lot in common.

Here’s another case—this time, a textile town in the Southern U.S.

In 1933, a reporter with Fortune magazine felt he had discovered something unusual in American life during a trip to North Carolina.

Visiting the town of Kannapolis, founded two decades earlier by the Cannon textile company and slowly expanded, the reporter found it “Like a medieval city, [standing] aloof and self-contained in the midst of empty country, suspicious of strangers, loyal to its feudal lords.”

Kannapolis, he reported, was the biggest unincorporated town in America, with some 15,000 inhabitants, and “every foot of it is owned by the mills.” The town consisted of hundreds of tidy, white-clapboard millworker houses, 7 huge textile factories, the company-funded Cabarrus Memorial Hospital, a company commissary, the Cannon Memorial YMCA, and a newspaper, The Daily Independent, owned by the Cannon family. Although the police were on the county payroll, all other functions normally performed by government were under Cannon’s purview—fire-fighting, street maintenance, trash collection, schools, and utilities.

Atop the company’s Mill No. 1, a huge illuminated sign proclaimed the town’s sole purpose in life: THE LARGEST MANUFACTURER OF TOWELS IN THE WORLD, it read.

Charles Cannon, described by the Fortune reporter as “the foremost figure” in the U.S. textile industry and as a “round-faced, ruddy, and nervous” executive, was head of the company and virtual lord of the town from the 1920s until his death in 1971. Such was his power locally that, in 1969, The Wall Street Journal likened “Mr. Charlie” to Monaco’s Prince Ranier.

So you can see that, like Lowell and Oak Ridge, company control was all-enveloping.

Also like Lowell and Oak Ridge, Kannapolis was a city built from scratch. It took existing textile-making technology—but the Southern mills constructed at this time were not saddled with old equipment, and had the advantage of being able to acquire state-of-the art looms. And like the two places that I have mentioned before, southern mill towns depended upon unskilled labor—often that of children.

Coal-mining towns, from Ohio to Pennsylvania, West Virginia, and Colorado, shared many similar attributes: all housing owned by the mine owning companies, all law enforcement and government, any health-care facilities or recreational facilities, owned and controlled by the companies. Included were Urey and Nanty-Glo, Pennsylvania; Jenkins, Harlan, and Wheelwright, Kentucky; and Logan, West Virginia. Many coal and copper mining towns went Lowell or even Kannapolis one better: In these, workers were required as a condition of employment to live in company-owned housing, and often required to shop at The Company Store. They were often paid in company-issued money, or scrip—which was redeemable chiefly at the company store.

By the 1850s, the Lowell companies had ceased to require workers to live in company owned housing. Nor was there the same effort at “moral policing”—no more required church attendance for example. But Lowell’s original impulse to subject the morals of workers to close scrutiny was imitated elsewhere.

Like these many towns I have already mentioned, Hershey, Penn. was built beginning in 1904 from the ground up as a home for chocolate maker Hershey Co. Founder Milton Hershey turned to the relatively remote Pennsylvania site for its proximity to dairy farms (needed for milk chocolate), a thrifty and industrious work force (which included many women), and as a place where he could erect a town where there would be “no poverty, no nuisances, no evil.” The factory was spread over 18 buildings, and the accompanying worker houses were equipped with indoor plumbing, central heating, and electricity. Workers were given a cornucopia of benefits, from insurance and medical coverage to a retirement plan. The company donated property and buildings for local schools and churches, including the Hershey Industrial School, a residential facility for orphan boys.

But there would be no democracy: Milton Hershey himself served as mayor, constable, and fire chief. Moreover, he was his own “moral police,” riding around town and taking notes as to which houses were not being well-maintained and receiving reports from private detectives as to which employees indulged in alcoholic refreshment.

Gary, Indiana, constructed beginning in 1906 by the United States Steel Corp., was also build from scratch. In need of further industrial capacity, the company paid $7.2 million to anonymously purchase a desolate stretch of Lake Michigan shore across the Indiana state line from Chicago. Again, the task of drawing up the town itself was left to the plant engineer. With the works occupying eight miles of shore frontage, the town was laid out as an unvarying grid, with subdivisions plotted out adjacent to the various U.S. Steel plants.

Steel labor—and coal mining for that matter—was performed primarily by men. And steel towns, from Lackawanna, New York, to Weirton, West Virginia, to Sparrow’s Point, Md., tended to be pretty rough-and-ready places. You couldn’t really enforce a moral code among such roughnecks, most managers seemed to acknowledge: “You can’t make a mollycoddle out of a mill man,” said Charles Roebling, head of Roebling Steel which in 1904 built the town of Roebling, N.J. Nevertheless, Judge Elbert H. Gary, chairman of U.S. Steel, was inclined to try to impose moral order in the city that had been named for him: For example, when an entrepreneur proposed opening a movie house in a company-owned building, Judge Gary agreed only if the company was allowed to review all films and allowed to veto any viewed as too racy. The movie house, it was further agreed, would also double as a venue for church services on Sunday.

So, to sum up, whether or not Lowell served as a model for company towns across the U.S.A., you can see a number of themes reoccurring: Towns built from scratch in undeveloped areas, with companies not only erecting buildings and streets but responsible for every kind of institution, from churches to recreational facilities, and even taking the place of government; the use of the latest technology; and a frequently paternal, even Big-Brotherish attitude toward workers, many of whom were women or children.

What about today? Are there still company towns being created?

In the fall of 2009, Google announced it was erecting a new corporate campus on Silicon Valley’s NASA base at Ames that would include employee residences. The Silicon Valley Mercury News estimated that housing there could take up 10% of the new campus’s space, meaning perhaps 60 2,000-sq.-ft. dwellings.

On top of that, the newspaper said, Google was encouraging the city of Mountain View, California–the location of its much discussed Googleplex–to transform the area around its headquarters, adding more housing and shops. The Googleplex already offers a smorgasbord of workplace amenities, from free food to nap rooms, that give work a homey, warm-nest feeling—and makes employees feel that they never need to leave.

Then in February, 2011, Facebook announced that it is moving its headquarters to the former Sun Microsystems campus in Menlo Park, California, and initiated a “community dialog” about how to develop the place. This August, The Los Angeles Times reported that construction there was booming, and that the complex would soon feature a score of merchants, from gourmet eateries to hair parlors, catering only to Facebook employees.

“It is the 21st century company town,” announced Silicon Valley futurist Paul Saffo. Yes, indeed: Both the Google and Facebook efforts sound more than a bit like the communities begun by Nathan Appleton, Charles Cannon, Milton Hershey, Elbert Gary, and many others.